The aim of this project is to add a 3D printed wireless charging tray to our MX-5e. The project will also include a USB C port for a charging lead (e.g. Apple Lightning) for direct connection. This project has initially been designed to work with Rob's iPhone 13 Pro Max.

Whilst we could use a genuine Apple MagSafe wireless charger (left in photo), we have opted to use a much cheaper Anker equivalent (right in photo). We have many Anker products and the quality is always excellent. We have deliberately chosen this model because it charges at the slower rate of 7.5W. This means the phone will not get as warm. It will obviously charge more slowly but this is not an issue for us. You can buy the Anker charging pad on Amazon

In the MX-5e the 3D printed charging tray is going to sit, where the removeable ash tray sits. In all the cars we have seen, this look pretty grim and never seems to match the centre console. It is a removeable unit made out of metal and plastic though.

The design is going to be 3D printed in three parts, which clamp the anker wireless charger in place. The tray features holes for the cable entry and also a recess to allow the phone to be extracted for the tray. The internal tray is a custom design to fit each model of phone (it will be for Rob's iPhone 13 Pro Max with it's Apple case on initially). It also features a recess for the camera lenses and surround to sit within, ensuring that the iPhone 13 Pro Max sits flush in the tray and on the charger.

We started by taking the ash tray out to measure it. It is simply held in place by two spring clips. We were surprised to see a cable entering the side of it through a rubber grommet. Closer inspection showed that someone had already fabricated a wired charging tray for an older iPhone and cut a hole, enable the USB cable to pass through. We ripped all this out. This must mean there is a dc-dc converter lurking under the dash, on the other end of this cable.

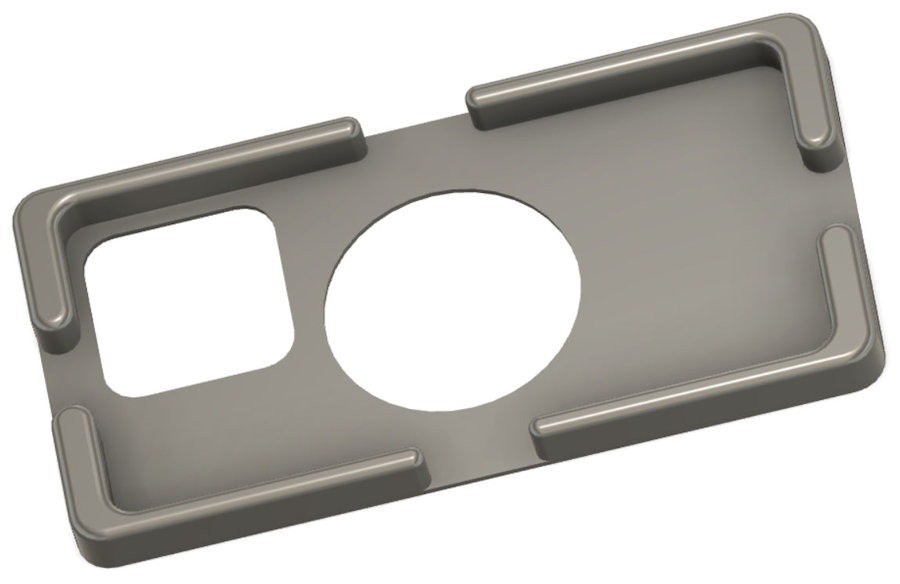

The first test print enabled me to refine the ergonomics and measurements. It took over 5½ hours to print. It fits the ash tray base really well and the 4 screw holes are in the right places.

Our second 3D design had more gaps in the surround to make it easier to lift the phone out and to also support a cable at either end/orientation. We also added a cut-out for the iPhone 13 Pro Max cameras.

To provide more support and to make it easier to fit the Anker charging pad in place, we also 3D printed this support. It is glued to the underside of the mount.

There is a USB C plug on the end of the Anker charger and this will need to plugged into a dc-dc converter (with a high power 5V dc output), which will be hidden under the dash. We also plan to use one of the many spare switches in the MX-5e to allow us to isolate the 12V feed to this dc-dc converter.

We use these dc-dc converters a lot in numerous projects. They provide a USB port that can deliver 15W.

This is the above 3D print painted in satin black to match the rest of the MX-5e interior. I've used some thin black foam on the underside, on which the iPhone camera module sits.

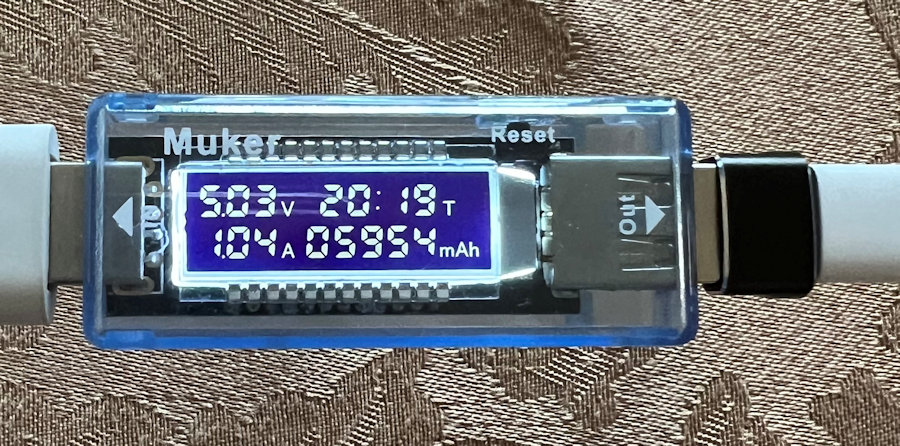

This little tool allows you to check the voltage and current being delivered via a USB port. You have to be a little bit careful using this device and the adapters used to connect it in-line. Both can actually change the way a phone charges and thus the amount of power is uses.

Using a genuine Apple MagSafe charger and a genuine Apple 20W power supply, we saw our iPhone charge using 2.2A or 11W. When we swapped to the Anker charger, we saw 1.1A or 5.5W. We then swapped out the Apple charger for our CPT dc-dc converter and again saw 1.1A or 5.5W.

In keeping with the philosophy of the OSSEV® project, we share our designs for free use by individuals. If you would like to use these designs for commercial use, please contact us for permission and to be added to our list of suppliers.

If you download the iPhone version with cut-out for the protruding camera lenses, then please consider making a small donation to help us deliver on all of the OSSEV® project objectives.

If you download the Plain version with no cut-out for a camera lens, then please consider making a small donation to help us deliver on all of the OSSEV® project objectives.

You will be able to buy the 3D printed parts for this project in our shop very soon.