This is the basic cooling system design in the engine bay, showing the aluminum pipes (grey) and the silicon hoses (blue) required. The system is designed to be self-purging of air, with the header tank mounted at the highest point on the bulkhead between the cabin and the engine bay.

There are four temperature sensors connected to the Driver Control Unit (DCU) for monitoring, in addition to the temperature controlled fan switch and the inverter & motors internal temperature sensors.

The goal is to keep the cooling system compact and lightweight, with plenty of monitoring so that we can monitor its performance. To keep things simple, we are using components with 19mm inlets and outlets, to match the Nissan Leaf inverter and motor. The Tesla water pump is sucking water through the system and sits on the "cold" side of the radiator. Any air in the system is purged into the header tank.

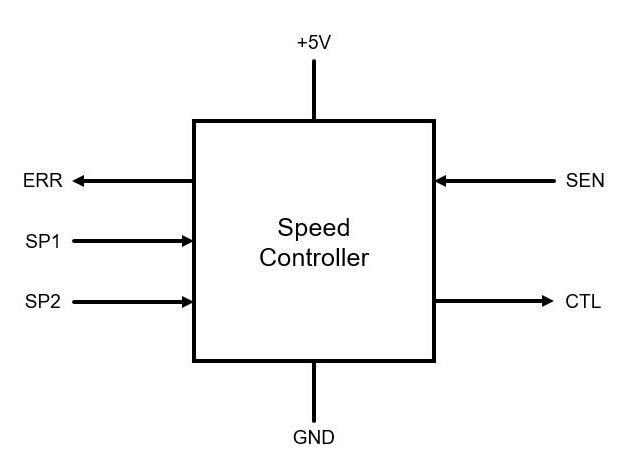

The electric water pumps are speed controlled by the Driver Control Unit (DCU) based on the observed temperatures. They have to be running all the time (when the car has been started), in order for the coolant to pass through the temperature sensors. At it's lowest speed it uses little power.

The radiator we are using in the MX-5e is small enough to fit behind the front bumper and sits behind the front air intake.

This is the aluminium radiator we purchased from Apollo Racing. The overall size is 634mm (H) × 260mm (W) × 65mm (T), the core size is 500mm × 200 mm × 56mm and it weighs 2.2kg. The inlet and outlet are a convenient 19mm, to match the rest of the cooling system.

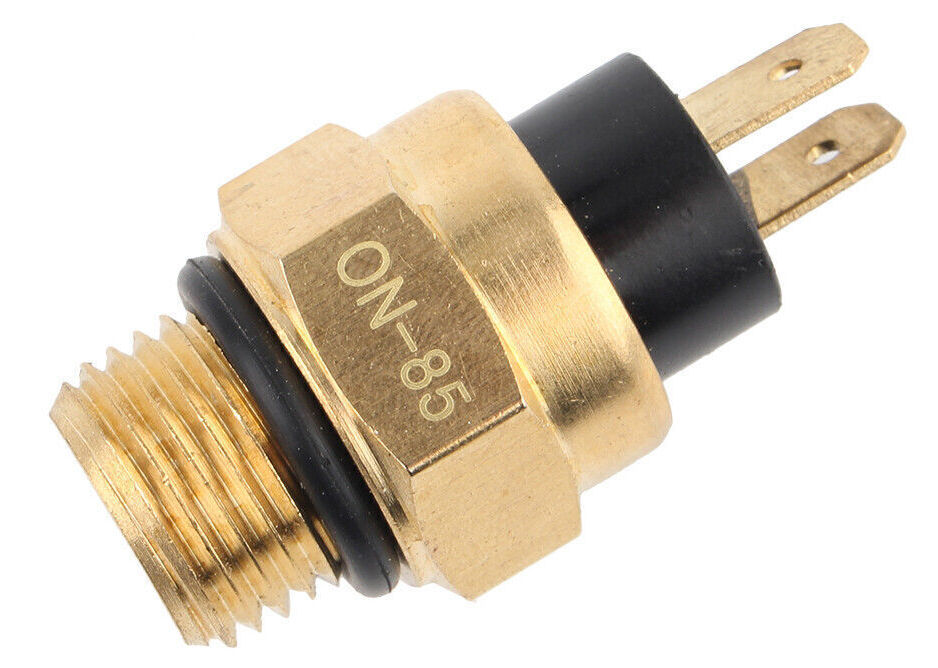

The radiator has a threaded insert for an M16 x 1.5 temperature controlled fan switch but, came with a screw in blocking cap. We no longer plan to use a temperature switch for the fan control.

The original intention was to use a radiator fan switch that screwed into the boss on the radiator, to operate the fan when the temperature exceeded something like 50°. This temperature switch would operate the fan via a relay.

The Nissan Leaf EM57 motor will start limiting power at about 80°C. Lithium batteries start derating at 35° and become dangerous above 60°C. These two conflicting requirements on the cooling system have meant that we have now placed the fan under intelligent control by the primary ESP32 used in our Driver Control Unit (DCU), since it monitors the temperatures at various points in the cooling system and is best placed to control the radiator fan.

The 8" radiator fan is intelligently controlled by the Driver Control Unit (DCU) based on measured temperatures at various points in the cooling system. The fan is rated at 80W and so it uses a relay, which also lights up a green fan visual indicator on the dash.

We are using this Tesla variable speed, electric water pump for the cooling system in our MX-5e.

We are developing a custom pump speed controller as another open-source project, which is used by our Driver Control Unit (DCU) to intelligently control the pump speeds.

We are using silicon hoses for the cooling system. This is just some of them. Longer runs use aluminium pipes with beaded ends. All of the hoses are fitted with stainless steel Jubilee clips.

We are using stainless-steel Y connectors at two points, to split the water leaving the header tank and to merge the flows into the radiator.

We bought this aluminium 1.2 litre header/expansion tank from Apollo Racing, to mount on the bulkhead in the engine bay. It is 140mm (H) × 115mm (W) × 76mm (T), with a ⅜ NPT side port and an ½ NPT bottom port. It weighs 425g.

We have fitted two 19mm brass hose tails to the inlet and outlet ports.