We have spent just over £12,000 on the MX-5e so far, so almost half way! 🤣 We are still on target for a total close to £25,000 including a full respray in an electric metallic blue. This doesn't include consumables such as paints and oils purchased.

DHL delivered the reduction gearbox this afternoon, from Inductive Autoworks in the USA 😎

The reduction gearbox bolts to the Nissan Leaf motor and reduces the output shaft speed by a factor of 1.8:1. This gives the MX-5e a top speed of around 109mph based on our transmission design and considerably improves the acceeleration.

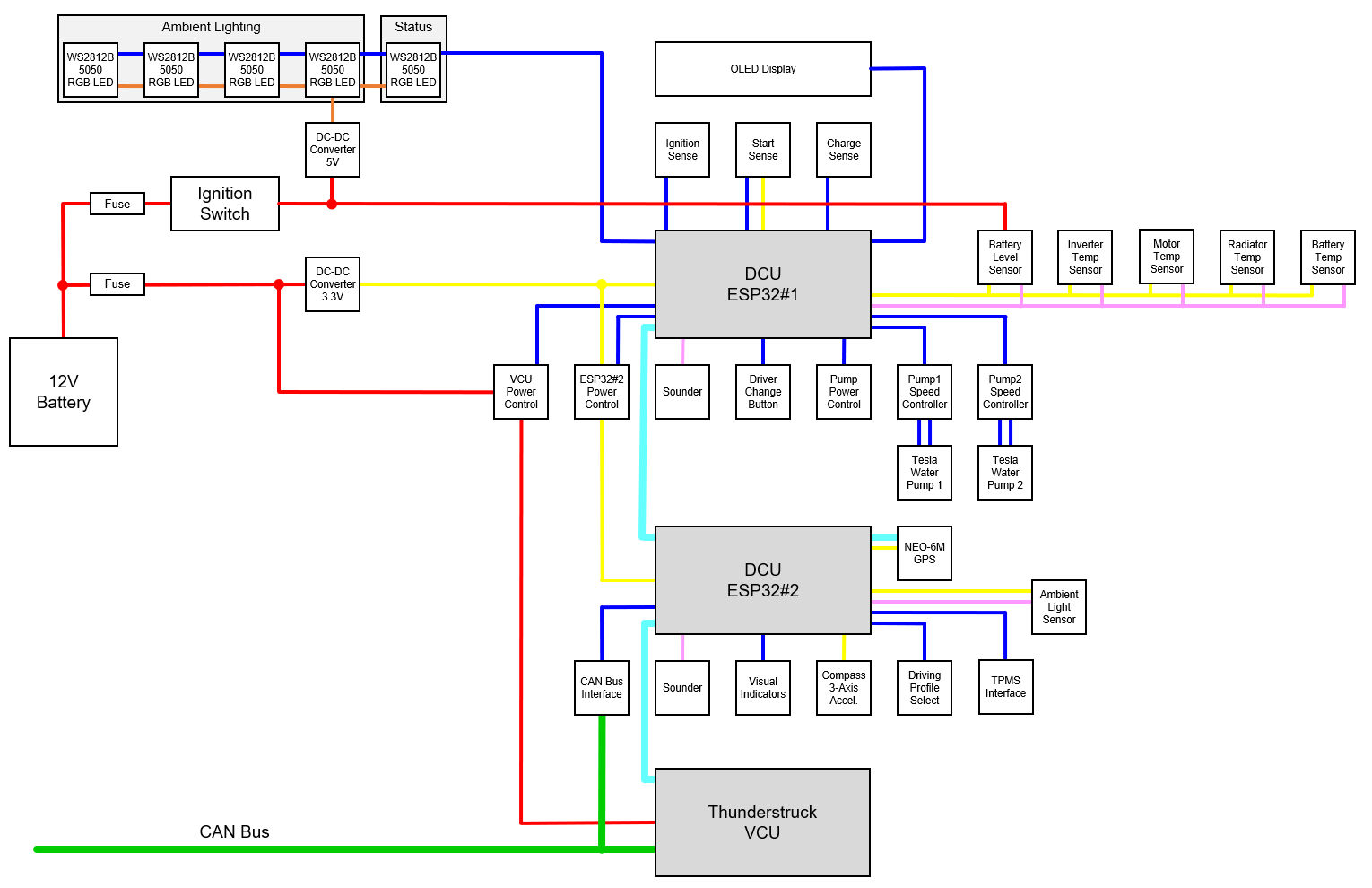

Rob has been really buy these last few weeks, designing, building and testing the Driver Control Unit (DCU). This also involves a fair bit of coding.

The fan switch arrived today, another part of the MX-5e cooling system project. It's an M16 × 1.5mm thread to match the threaded insert of the radiator. It closes at 85°C to activate the fan relay. It weighs 32g.

The radiator fan arrived in the post today, another part of the MX-5e cooling system project. With fittings, it weighs 815g.

With the arrival of the 19mm hose tails to fit the header tank, we have all the parts required to determine what silicon hoses are required to connect it all up. This is described in detail in the MX-5e cooling system project.

We don't quite have enough switches in the MX-5e for all of the functions we want to provide. Fortunately, there are three switch holes to the right of the steering wheel. One was used for a 3rd party fog light switch and the other two have blanking plates. We have designed and 3D printed a switch mount that can take one or two switches, either momentary or latching.

The two shown here are latching switches for the pedestrian warning system (green) and fog lights (yellow). There will be a single toggle switch on one for the side/main lights and another with two momentary switches for the pop-up headlight winking feature.

This is what our switch mount looks like installed. We will replace the existing fog light switch shown (on the right).

The ANL fuse junction box arrived today. It's very solid and weighs 322g. This is going to save a lot of weight and make the MX-5e 12V wiring much simpler.

The two main elements of the MX-5e cooling system project arrived in the post today. The first was this aluminium radiator. It weighs 2.2kg and fits perfectly in the space we have planned for it 😎

As part of the project to rewire the MX-5e, we are sorting out the switches and switch mountings. We have some blanks to the right of the steering wheel and have 3D printed switch mounts with custom labels.

In preparation for re-attaching the front sub-frame, we have cleaned up the fixings.

More work in the engine bay. We have cleaned up and fixed the bonnet stay. We have re-fitted the wiper motor and bonnet release cable, which meant sorting out the wiring loom grommets into the engine bay. We have wired up the pedestrian warning system. We are confident that we can locate the new 12V battery inside the engine bay.

We have purchased a compact aluminium radiator (634mm × 260mm × 65mm) to sit behind the air inlet in the front bumper. It has mounting points for a small fan. This one has 19mm inlet and outlets, which matches the rest of the cooling system. It's very small compared to the one that was installed but there is much less cooling required in an EV.

We have also bought a 1.2 litre aluminium header tank for the cooling system. This has two outlets, one at the bottom to feed into the inverter and the return inlet at the top from the radiator. We will find some 19mm hose tails to fit the inlets. We can get away with a tiny tank as the overall cooling system volume is small and this means it all weighs a fraction of the ICE cooling system that was installed.

Rob is reusing a lot of the learning from building his Fisher Fury R1 as we design and rewire the MX-5e electrics. A lot of effort was taken to get its 'on the road' weight to 450.5kg with half a tank of fuel including designing and installing a custom, lightweight wiring loom.

We have decided to use the same (as the Fisher Fury R1) lightweight (it weighs 4.2kg), Yuasa YTX12-BS 10Ah motorcycle battery in the MX-5e as we are confident it can handle the loads and meet all of the electrical demands we will place on it. This smaller battery will be easier to find a place for in the engine bay too. To put this into context, we removed 4kg of redundant wiring from the engine bay and another 2kg in redundant metal brackets, on top of the 178kg engine and gearbox. The battery we are replacing weighs 11.4kg.

Another weight saving approach in the MX-5e is to use this three-way ANL fuse splitter from the 12V battery to the ignition switch, unswitched blade fuse holder and the dc-dc converter. This replaces a much larger and heavier box that was inside the engine bay.

We removed loads of redundant brackets (and weight) from the MX-5e engine bay. A few of them are useful and can be re-used though. This one is the mount for the fuse box and we are reusing this for our custom blade fuse box as we rewire the MX-5e. It has been cleaned up and painted.

More progress in the engine bay today. The plan is to work out where everything should sit. We are looking at a very small 12V battery within the engine bay. There is loads of room for our small radiator and fan unit behind the front bumper.

We are starting to wire things up in the engine bay and work out where everything is going to fit. We are starting with the bits that have a fixed location such as the pop-up headlights, windscreen washer bottle, iBooster, etc. The rest can optimally located around these parts. We have also identified and tested suitable earthing points. The new fuse and relay boxes are going to sit on the right side (left in this photo), with the liquids and cooling system components on the left.

We fitted the new horns, wired them up and tested them. These fit properly and clear the chassis nicely.

The Buzzweld WAR black underseal arrived in the post today, so once the weather warms up a bit, we can complete the underside of the car. We can then refit the brake lines.

Started looking at refitting the headlight units and decided they need a bit of TLC too. The actual headlights are sealed halogen 50W/50W and not the brightest but, we are going to reuse them for now.

As part of the MX-5e rewiring project, we are fitting new H4 connectors and higher power wiring, to enable a modern halogen upgrade later. We use the headlights very little, so there is no point in fitting LED headlights to the MX-5e. It makes MOT/IVA tests harder too, as the beam pattern never as good.

Whilst the headlight actuators and frames are in really good condition, the 'bowls' and retaining rings needed some restoration. These have been cleaned up and repainted satin black.

The headlight adjuster screws also needed some restoration. New ones are hard to get hold of but, these look much better for a clean up.

We have started rebuilding inside the engine bay with the intention of starting the MX-5e Wiring. Attempting to refit the old horns showed that they cannot be mounted nicely in their previous location and that the previous fitment was a bit of a bodge. It's is going to be much simpler, to just buy some new ones that fit nicely, so that's what we have done.

We have started ordering loads of bit from Vehicle Wiring Products, including lots of cable in various colours to match our wiring diagram. Rob used them a lot when he built his Fisher Fury R1 and the quality of the stuff they sell is very good.

As part of our OSSEV/MX-5e display project we are using this small OLED display and have been making great progress in getting it connected to our Driver Control Unit (DCU). The focus is currently on getting the fonts, layouts and information 'views' correct, before we look at more advanced features like brightness control and mixed font brightness.

It didn't take long to complete most of the 'views' that we require 😎

We have finished respraying on the inside of the engine bay.

We can now start to rebuild the front end and fit the new front sub-frame and suspension components. We can the fit the iBooster and work our where everything is going to go. The pop-up headlights, radiator, steering rack, etc. are all pretty much fixed in their location. We need to work out where the Nissan Leaf motor will sit and where the inverter will need to be remotely mounted. The 12V battery will also need to fit in the engine bay.

January 2025 •

February 2025 •

March 2025

January 2024 •

February 2024 •

March 2024 •

April 2024 •

May 2024 •

June 2024 •

July 2024 •

August 2024 •

September 2024 •

October 2024 •

November 2024 •

December 2024

January 2023 •

February 2023 •

March 2023 •

April 2023 •

May 2023 •

June 2023 •

July 2023 •

August 2023 •

September 2023 •

October 2023 •

November 2023 •

December 2023